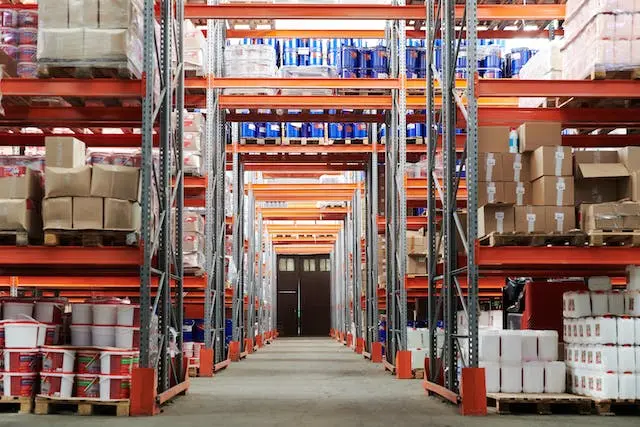

Smart component storage for electronic board assembly is a tactic employed by businesses looking to uphold high standards for their offerings. In order to avoid errors and guarantee the best possible use of the resources at hand, this method integrates a number of technologies.

Following this development, logistics consistently introduces a range of technologies to streamline the transportation of goods within a warehouse.

This article explains the idea of smart storage, including its key benefits, and the technology that makes it possible.

Read also: Top 8 Applications of Artificial Intelligence in The Supply Chain

What is smart warehousing?

Smart warehousing is a sophisticated inventory management approach that maximizes the transportation, storage, and distribution of goods and materials within the company by utilizing data analytics and state-of-the-art technologies.

This strategy seeks to save expenses, minimize errors, boost operational effectiveness, and expedite response to market demands.

Automated systems like robotics, IoT (Internet of Things), and machine learning algorithms, which monitor and control the flow of goods more effectively than conventional techniques, are at the core of smart warehousing.

In order to facilitate more precise decision-making, smart warehousing also entails gathering real-time data on inventory performance and market demand. This enhances inventory forecasting and enables businesses to modify their warehousing operations in response to demand variations.

Advantages of smart warehousing

Numerous noteworthy benefits that come with smart warehousing have a good effect on businesses’ competitiveness and operational effectiveness. It makes it possible to optimize storage capacity, making better use of the available physical resources.

Furthermore, smart warehousing reduces human error, increasing the accuracy of inventory tracking and lowering losses. Accelerating material handling processes can lead to time savings and increased production, which is an additional benefit.

Decision-making that is more aggressive and agile is made possible by real-time data collection and analysis, which enables prompt adjustments in response to market needs. Moreover, smart storage lowers operating expenses, minimizes waste, and boosts the effectiveness of the inventory control procedure.

Additionally, it improves supply chain visibility, which facilitates product tracking and deadline compliance, enhancing competitive advantage and improving customer satisfaction.

Technologies that contribute to smart storage

Error rates decrease with the number of process management tools available to an organization. Every procedure and technological advancement in a specialized CM (configuration management) is intended to guarantee the delivery of high-quality services.

Thus, enterprises that want to integrate smart storage but do not intend to assemble electrical boards are unlikely to do so successfully. This is due to the following features of specialized environments:

Inventory Management Systems

The organization needs real-time access to key stock information, like the following, for intelligent storage to succeed:

- Product location accuracy;

- Obsolescence dates;

- Travel information;

- Preservation.

It’s risky to not organize all of this data into information banks because there’s a probability that mishandling will result in loss. To make sure that nothing is overlooked or lost, a smart warehouse’s system has tracked every item as well as movements and specifics.

Smart shelves

These shelves have sensors mounted on them so they can tell when a product has been taken out. They ensure the rapid delivery of information to the management system. The system receives immediate notification of any movement without requiring a manual relay of the event.

For instance, this avoids information gaps between what is predicted and what is retrieved.

Efficient barcodes

Everything in the smart warehouse has the proper labeling. Very similar products cannot be confused thanks to barcodes because they have distinct codes and are constantly inspected.

This verification is crucial for electronic boards since they are identifiable when they leave the factory. Now, instead of being done by hand, this identifier is laser engraved.

Blockchain

A safe and unchangeable record of product movements and transactions is provided by blockchain technology. This guarantees increased traceability and transparency across the supply chain, lowering fraud, and mistake rates and enhancing information reliability.

Furthermore, blockchain facilitates the process of product provenance verification, which is crucial for both regulatory compliance and product quality.

Big Data and Data Analysis

Large volumes of information can be gathered and processed in real-time thanks to big data and data analysis. This makes it possible to spot trends, estimate demand more precisely, and optimize storage operations.

Data analysis also contributes to more forceful decision-making, lower operating expenses, and increased supply chain efficiency, all of which lead to more flexible and successful inventory management.

Machine Learning and Artificial Intelligence

Artificial intelligence and machine learning technologies are crucial to smart warehousing because they automate difficult processes like demand forecasting and product routing. These algorithms increase productivity, decrease errors, and optimize inventory processes by learning from historical data.

Additionally, they provide real-time insights that help with inventory management and adaptability to changing market needs.

They also offer instantaneous insights that support inventory control and flexibility in response to shifting market demands.

In conclusion, smart storage revolutionizes the landscape of electronic board assembly and warehouse logistics, offering a myriad of benefits to businesses aiming for operational excellence and competitive advantage. By harnessing cutting-edge technologies such as robotics, IoT, machine learning, and blockchain, smart warehousing optimizes inventory management, enhances supply chain visibility, and enables agile decision-making.

From efficient barcodes to sophisticated data analytics, each component of smart storage contributes to error reduction, cost savings, and improved customer satisfaction. As businesses continue to embrace innovation, smart storage emerges as a cornerstone strategy, empowering organizations to navigate the complexities of modern commerce with precision and efficiency.