The Future of Supply Chain: 5 Critical Changes to Make Today

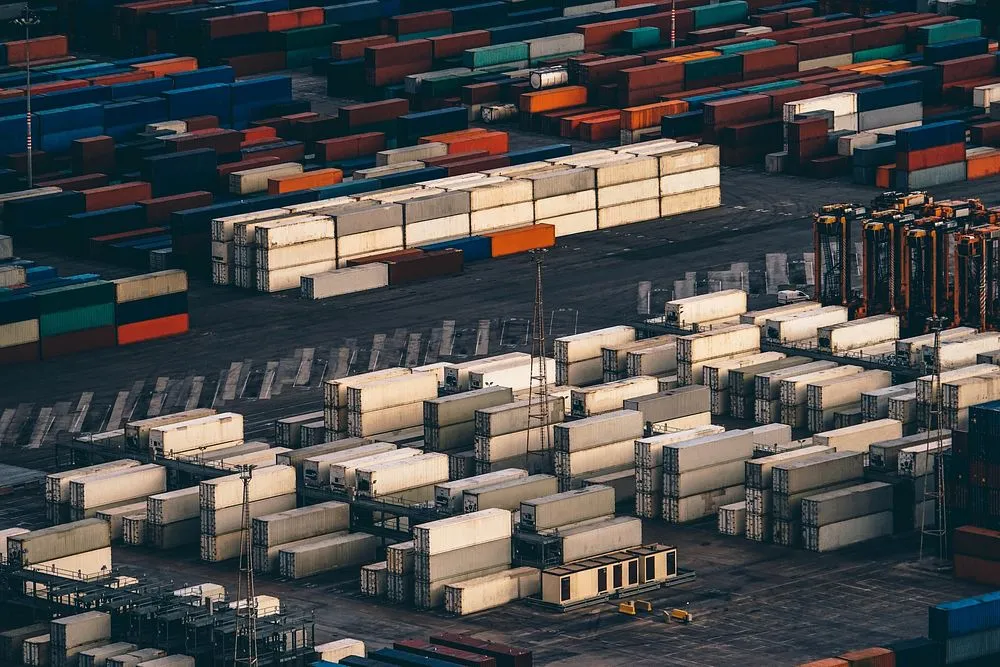

The Covid-19 pandemic has set off a period of profound change that we are currently experiencing. Both the supply chain and society as a whole were impacted by these shifts. Today’s diverse difficulties have demonstrated the need for applying certain tactics in order to change course. From manual to digital, from worldwide to local, from offline to online, and from in-person to remote. There is much to be done, and we must act immediately.

The present changes include opening up new business models and a new management vision in addition to investing in technical tools for the operation.

According to a study conducted by the global technology research firm Gartner, 38% of supply chain executives worry that their companies are not set up to handle the problems that lie ahead for the next two years. According to the group, the COVID-19 issue sparked a significant shift in logistics firms, but more significant change is still to come.

Gartner has identified five shifts that will occur over the next five years under this new situation. Through this article, you will come to know them. Prepare yourself to enter the supply chain of the future!

Read also: Top 4 Logistics Automation Trends That Everyone Should Be Aware Of

5 Changes to Make in Your Supply Chain Today

The five changes to the supply chain that Gartner is focusing on over the next five years are digitization of the supply chain; globalization and offshore; new business models; migration to e-commerce; and remote and dispersed teams. You must be inventive, flexible, and have a solid framework in order to adjust to them. You should also rely on cutting-edge technologies. The most crucial thing to remember is to prioritize the customer experience.

See the specifics of these modifications as well as Garner’s predictions for the supply chain’s future below.

1. Digitization of the supply chain

Gartner reports that by 2025, twenty-three percent of supply chain executives anticipate having a digital ecosystem. For these people, the next ten years will see a significant shaping of commercial potential due to digitization.

With the use of technologies like the Internet of Things (IoT), digital twins, and blockchain, which can improve network collaboration, visibility, and risk management, the organization is able to achieve more resilient and flexible logistics. Gartner claims that digitalization and real-time end-to-end information exchange enable businesses to react more quickly and effectively to unforeseen shifts in supply or demand.

2. Globalization and offshoring

In the next five years, 46% of supply chain leaders expect a fall in globalization, and 61% expect a decline in manufacturing outsourcing, according to the recent Gartner survey.

Experts from Gartner believe that the current state of globalization is under strain because of complicated supply chains, consumer demand for products made in other nations or continents (such as China’s IFA for vaccines), more capital turnover, and longer lead times. In this regard, it is advised to reevaluate offshore and network strategies and find a balance in reshoring in order to control costs, address tax ramifications, and take advantage of local market opportunities. Thus, the approach needs to focus on reestablishing the equilibrium between local, regional, and global chains.

Garner envisions a situation in which manufacturing diversification—which was already under progress prior to 2020—is sought after in order to enhance resilience and agility. “Almost half of supply chains will move production to different countries or regions. Companies will invest in localized sourcing aiming for resilience, agility, and sustained growth in local markets – for example, training small local companies to manufacture for global supply networks”, highlights the agency.

3. New business models

A Gartner study found that 79% of supply chain executives believe the new business model to help post-pandemic recovery is an internet/platform-based strategy. The group predicts that CEOs will use the chance to “reset,” or reconstruct, their companies for the new normal.

In order to do this, supply chain tactics must be reviewed and adjusted to fit with new business models. This entails keeping an eye on demand-side costs as well as consumer segmentation. Supply chains will acquire the operational skills necessary to fulfill each of the goals linked to various values, predicts Gartner.

4. Migration to e-commerce

Additionally, according to the Garner survey, 69% of supply chain firms predict that over the next five years, consumer willingness to visit stores will decline.

The government’s blockades and the public’s fear of Covid-19 contamination led to a decline in foot traffic in physical stores. Spending by consumers on e-commerce increased, which hurt businesses that did not open up shop online or even integrated their online and offline platforms.

Therefore, in order to provide the customer with outstanding service, changes must be made as soon as possible, optimizing logistics. Building scalable capacity, including online buying and returns service, and reevaluating network design to enable a more profitable operating model that supports the volume shift to e-commerce are among the recommendations made by Gartner.

According to Garner, businesses will make an attempt in the future to provide the greatest possible shopping experience and cater “to the extreme” to each customer’s tastes. Offering individualized goods and services that are accessible wherever, at any time, is part of this. Investing in the appropriate tools will result in lower costs and a better customer experience.

5. Remote and distributed teams

Lastly, an important statistic from Gartner: 98% of supply chain executives see a rise in remote work over the next five years.

Logistics companies have traditionally been culturally built around local, face-to-face work. However, this scenario started to shift with the epidemic, and it seems like it will keep evolving. Garner advises employers to “showcase empathy and flexibility.” Encourage the use of a hybrid workforce and create strategies for raising remote teams’ output.

Experts from Gartner predict that supply chain companies will have a hybrid workforce in five years, alternating between in-person and remote labor. The rise in remote employment will provide the organization with easier access to talent. “Technologies for tracking productivity will be widely used, as will virtual practices for recording time and monitoring computer use. Physical plants, warehouses, and corporate offices will continue to exist, but they will increasingly become spaces for collaboration and innovation”, highlights Gartner.

Is your company ready for these supply chain changes?

The changes that Gartner has identified are already in operation. This is the ideal moment to start implementing them in your organization, always striving to strike a balance between customer-centricity and business success.

To accomplish both goals, it is necessary to be ready for both the present and the future. Accordingly, Gartner identifies the key movements as “benefiting all parties involved,” “being purpose-oriented,” “focusing on innovation and collaboration,” and “taking positive measures to improve environmental and community well-being.” Today is the beginning of the change!

Do you want to guarantee the supply chain’s future success for your company? Reach out to us immediately.