top of page

All Posts

Why Direct Relationships with Class 1 Railways Change the Game for Shippers

Image Source: iStock | Why Direct Relationships with Class 1 Railways Change the Game for Shippers In North American logistics, rail is not just another transportation option. It is a strategic advantage. For bulk shippers, manufacturers, and cross-border operators moving high-volume freight, rail capacity, scheduling reliability, and network access can determine whether a supply chain runs smoothly or faces costly disruption. Yet many companies do not realize that not all ra

4 days ago5 min read

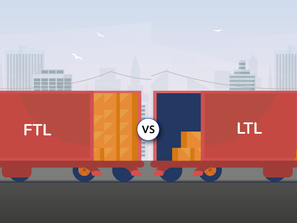

FTL vs LTL Cross-Border Freight: Cost Comparison, Transit Time & Best Option for Canada–U.S. Shipping

Image Source: Pixabay | FTL vs LTL Cross-Border Freight: Cost Comparison, Transit Time & Best Option for Canada–U.S. Shipping Shipping freight between Canada and the United States isn’t as simple as choosing a carrier and booking a load. Capacity fluctuations, customs clearance, transit time variability, and cost volatility all play a role in determining the right transportation strategy. One of the most common questions businesses ask is: Should we choose FTL or LTL for cros

Feb 244 min read

Understanding the Difference Between Food-Grade and Regular Warehousing

Image Source: Freepik | Understanding the Difference Between Food-Grade and Regular Warehousing Warehousing plays a central role in supply chain operations, but not all storage facilities are built to handle the same types of products. For businesses dealing with food products, choosing between food-grade and regular warehousing is not just a logistical decision, it is a compliance, safety, and reputation decision. Food manufacturers, importers, distributors, and retail suppl

Feb 174 min read

Key Factors That Influence Freight Planning and Logistics Performance

Image Source: Key Factors That Influence Freight Planning and Logistics Performance Freight planning plays a critical role in how efficiently a supply chain operates. While it is often viewed as a scheduling or cost-related function, effective freight planning goes much deeper than choosing carriers or negotiating rates. It directly influences delivery reliability, inventory flow, customer satisfaction, and overall logistics performance. As supply chains become more complex a

Feb 104 min read

What Businesses Should Know About Temperature-Controlled Warehousing and Transportation

Image Source: iStock | What Businesses Should Know About Temperature-Controlled Warehousing and Transportation Temperature-controlled warehousing and transportation play a critical role in modern supply chains, especially for industries dealing with food, pharmaceuticals, chemicals, and other sensitive products. From the moment goods leave production to the point they reach customers, maintaining the right temperature conditions is essential to protect product quality, safety

Feb 34 min read

What a 3PL Actually Does: A Complete Breakdown of Services

Image Source: iStock | What a 3PL Actually Does: A Complete Breakdown of Services Third-party logistics (3PL) is one of those terms businesses hear constantly, but rarely get a clear explanation of. Many companies know they “need a 3PL,” yet don’t fully understand what happens once freight leaves the supplier, arrives at a warehouse, or moves across borders. This guide breaks down what a 3PL actually does, step by step, across the supply chain. No jargon. No buzzwords. Just a

Jan 274 min read

bottom of page